Not a very complicated project, but it was still a frantic couple of weeks getting it finished in time. I used a cute little 6 volt submersible food-grade pump which was being sold on Amazon for sous-vide cooking purposes. The bike was $3 from Goodwill, and I rigged up a simple tachometer using a $5 used bike computer. The non-contact magnetic sensor was just a reed switch, so it was trivial to detect it closing when hooked to an Arduino.

|

| Photo by Jen Kale'a |

It had flashing lights, a progress needle hooked to a servo, and a buzzer playing happy and sad noises to tap as many addictive gamer impulses as possible. Plus, of course, random positive feedback. The progress needle has to increment 15 times in order for a unit of alcohol to be dispensed. As long as you're pedaling, it will keep incrementing about every other second. Except that each time it does, there is a 4% chance of failure, which sends it back to the beginning. 0.9615 = 0.54, so you have slightly better than even chances of success each time you start. Each win provided about a third of a shot of the cheapest vodka I could find. Warm, cheap, slightly dusty vodka.

|

| Photo by Jen Kale'a |

It was fairly well received on the playa. We were camped farther out on 5:00 than we'd been hoping for, though, so there wasn't a huge amount of foot traffic. It mostly just confused people, I think. Most of the people who actually used it were the ones who knew what a Skinner Box was and got the joke from that level. I did catch one or two people engaging in classical Skinner Box behavior, though, developing complex theories as to when it would and would not dispense alcohol. We didn't go through nearly as much of the cheap vodka as I had planned for, so I spent some time on Saturday going around giving the surplus out to needful bars.

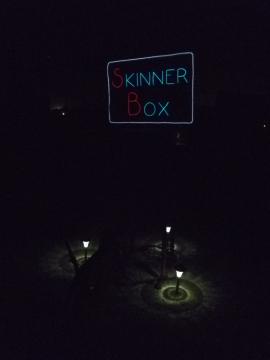

The el-wire sign I made for it turned out to be the best thing about it. It was a very convenient for finding camp at night. I was very pleased with its crisp, clean lines. I probably should only have used two colors of wire, though. I was going for a classic 50s neon look and I think the color scheme just looks kind of... toothpasty. Oh well.

|

| Photo by Jen Kale'a |

In the end, it was a fun project, but I won't be taking it back. I don't think I like doing static installations like this in front of camp. It encouraged me to just sit there waiting for people to come by. I want to be out and about, wearing and/or riding my art. I do have some other installation ideas, but they will be 1) bigger 2) more conceptually simple and 3) on fire. As they should be.