I mounted the pump arm struts finally. This ended up being super fiddly and generally not as perfectly symmetric as I would have liked. But I'm happy enough with the final look -- all those hours at the forge were worth it!

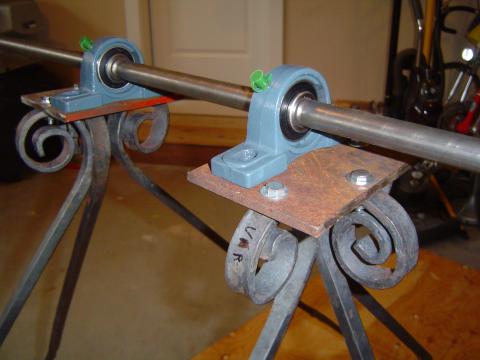

I also cut some plates for mounting the pillow blocks for the pump arm pivot. They will need to be shimmed a bit for their final mounting, and I need to grind some more graceful curves into them.

I had been thinking of forging the drive wheel brackets, so I prototyped one yesterday. It was, simply put, a massive flaming pain in the ass. It's just too big to be worked in my little forge very easily, making it almost impossible to do the kind of fine tuning something like this would need. Starting to think I'll just weld up some very simple brackets out of angle iron.

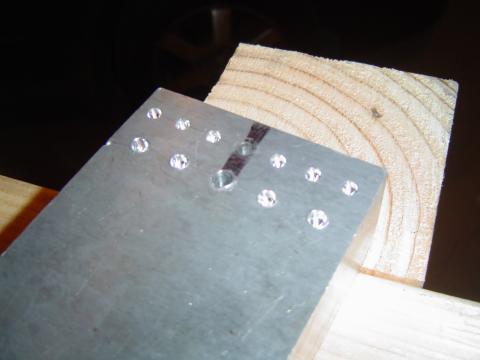

I wanted to start working on the chain drive, but first I needed a chain breaking solution. So I made a anvil for driving the pins out, with divots spaced for both the #35 and #40 chains I'll be dealing with. (No, working with multiple chain sizes was not my idea. The differential came with a #35 sprocket, and bike wheels of course use #40.) Chain sits fairly well with the rivet heads nestled down like that, and the central ones are drilled extra deep so I can drive the pins out with a punch after grinding the head off. Another excellent use for a chunk of Boeing Surplus aluminum!

And this is what it got me -- a completed chain drive for the crankshaft to differential connection! The action felt nice, though it can't handle any load of course until I get the keyways cut. A little worried I might have geared things down too far, but swapping out sprockets wouldn't be very hard.

I really like the pump arm struts. They look far too fragile for the job, which is always a plus - as long as they actually work, of course. ^_^

ReplyDeleteThey're pretty solid, when the bolts are tightened down nicely. My only concern is the torque that the pump arm will be able to put onto them, if pushed sideways instead of up and down, like if someone stumbles against them. Which, let's be honest, could just possibly happen when riding around on a rickety and deeply impractical platform in the middle of a duststorm while maybe not entirely 100% sober. :)

ReplyDelete